[ad_1]

Many people have plastic home windows at house however have you learnt how they’re made? Why do they considerably scale back noise, why doesn’t moisture get inside? To get solutions to those questions we’re going to the Kransoyarsk firm “Okno” (“Window”) which makes home windows for town.

That is the primary constructing of the corporate.

The method begins from glass chopping.

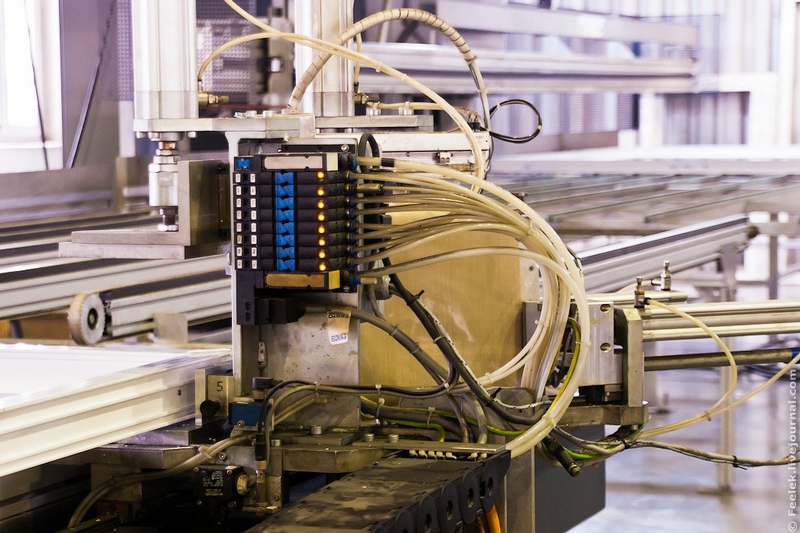

Such a machine helps to chop it.

Glass isn’t clear when arrives so it’s cleaned first in a particular machine.

Primarily they make triple-pane home windows. They supply a enough stage of warmth and sound insulation.

Glass spacers are positioned in between. Additionally they pour dehumidifier contained in the body.

The first layer of sealing is utilized on the body at this stage.

Now it’s flip of the second sealing layer.

That is how they retailer sealant.

Heavy glass is lifted by such sucking cups. They will stand up to greater than 100 kg.

Elements transfer on such a conveyor.

Prepared glass.

It’s the store view from above.

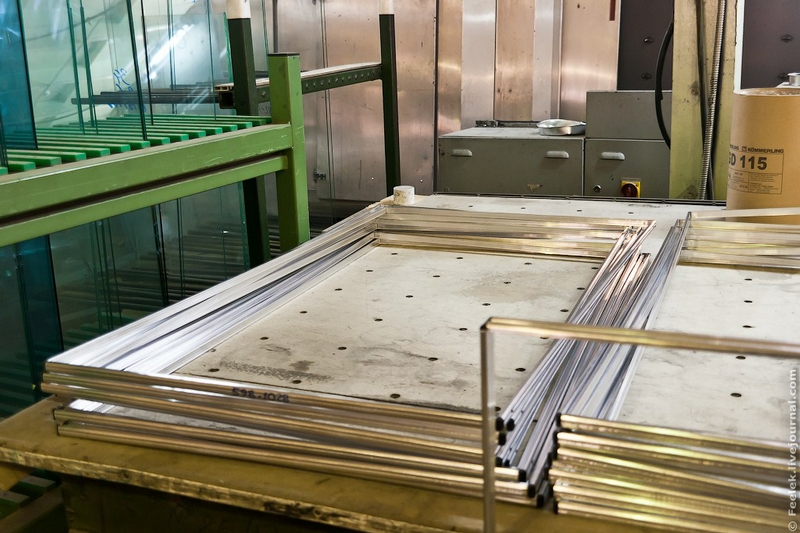

Right here they make PVC profiles, repair fittings and do glazing.

This car transports cargoes from one store to a different.

Each glass is marked.

They’re positioned right here, on the specil place.

Reinforcing profile is the profile ingredient from galvanized metal, put in inside the primary profile. It helps home windows to face up to heavy masses.

It’s minimize with such a machine.

PVC profile is the primary part of plastic home windows.

It’s minimize with a noticed…

.. or by this machine.

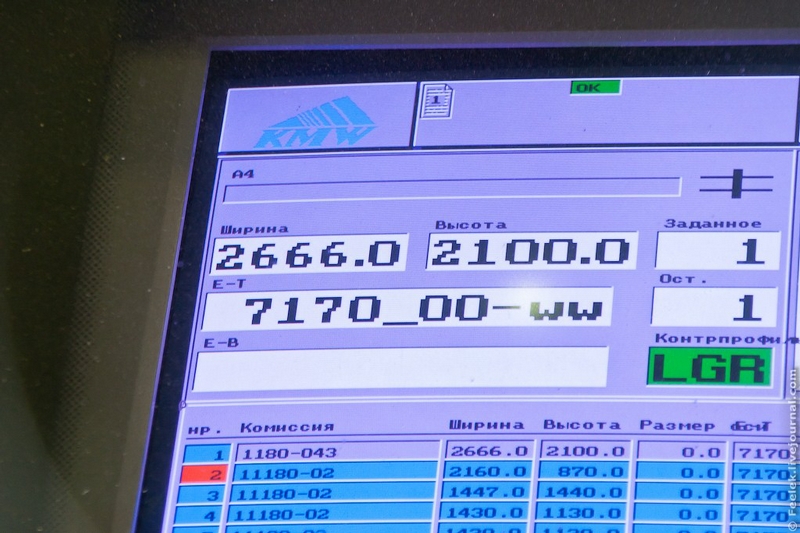

It’s the management panel of the machine.

Waste is put in massive sacks.

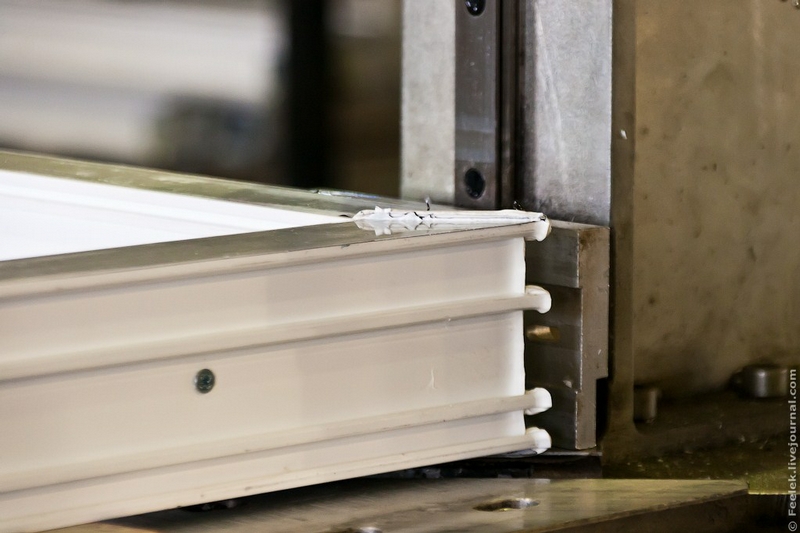

The minimize elements of profiles are to be related.

For this it have to be heated.

Two elements are heated and related.

The machine has 4 welding heads.

The temperature of the welding knife is 230-250C.

Uneven elements are smoothed.

This machine is to do it.

The machine doesn’t need assistance of individuals.

The workpieces are blown via with compressed air after which positioned on particular racks for storage.

It is a comparable machine however not an automatic one.

The additional future of the profile relies on its goal – it will possibly turn into a window, a door or a partition.

They make holes for mounting all different parts.

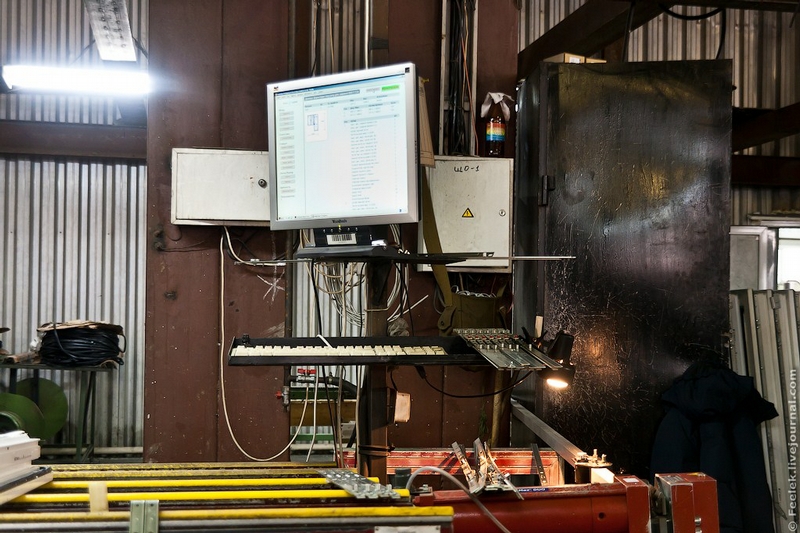

The will be additionally made by drilling machines.

All these actions are accomplished in accord with the scheme (every window has its personal).

Screws are tightened in two methods: by a screwdriver…

… or by this machine.

And here’s what they get in end result.

It’s the sealing rubber.

Then a glass is inserted into the body which calls for abilities of employees.

The extra uncommon the form of the window, the extra guide work is required.

Some individuals desire home windows with protecting movie or a movie with a sample.

They want particular glue to repair the movie.

And this store is for making facades.

A number of machines are used for chopping reinforcing parts of the facade.

Generally glass breaks, in fact.

Some supplies are saved exterior.

And at last we transfer to the warehouse of prepared merchandise.

Right here merchandise are loaded into vans and transported alongside town.

Let your private home be heat and cosy!

by way of feelek

[ad_2]

Source link